Sustainable Production System (SPS)

Our Works SPS

Sustainable Production System

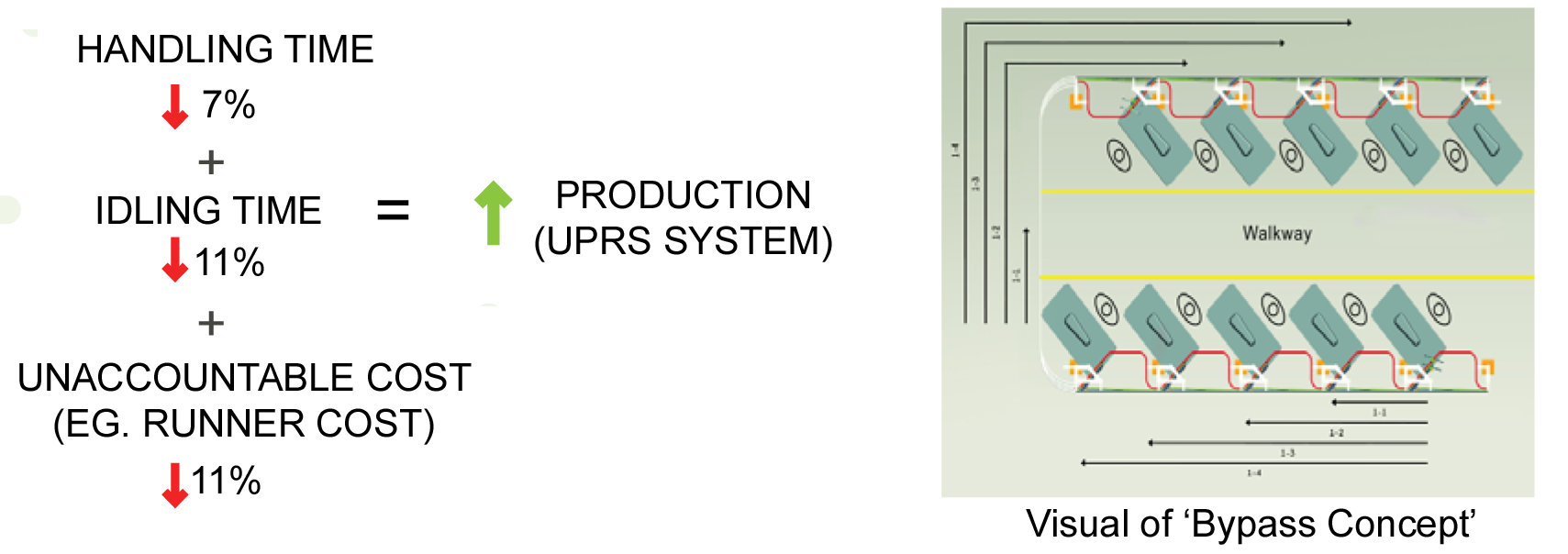

The SPS model demonstrates the flexibility and variations of line management. Combination of the Inner and Outer U to form "one single" sewing line which allows the management to fully utilize all the required work stations.

Specification

- Stations per Line : Customizable

- Hangers per Station : 9

- Width x Height : 3.9m x 2.4m

Option

- 1 watt led light fitted on sewing machine.

- Option of RFID data collection.

- Fitted led light.

- T-version lines

Includes

- Power supply setup : line circuit breaker, electric cable to individual station, international standard power plug.

- Air supply setup : air hose with connector to individual station, hose to main air supply.

- Coloured clips on hangers for easy identification.

- Manual counter specially design for simple data collection.

- Triple U connector.

- Mobile loading/unloading tables.

Features

Variation of Line Balancing

Less wip and beter visual line management.

Less Manpower

SPS is auto to flow the hanger from one station to the next station. No limitations to the number of product operations.

Multiple Products Within A Line

Loading at any stations thus can create any modular cells within a line. Flexibility of bridging all lines together for continuous/bigger line.

Clearer View of Garment Pieces/WIP (Work in Progress)

Reduce unnecessary work down time while the hanger to flow into station. Not easy to lost any part of garment.